High-pressure switches are smart gadgets that monitor and control pressure levels in various systems. These switches spring into action when pressure hits a certain mark, ensuring the system stays within safe operational limits—much like a lifeguard keeping an eye on swimmers at a busy pool. What’s more intriguing is that these switches aren’t exclusive to just one industry; they’re used broadly from HVAC systems to hydraulic machinery. Now let’s delve deeper, going under the hood of a high-pressure switch.

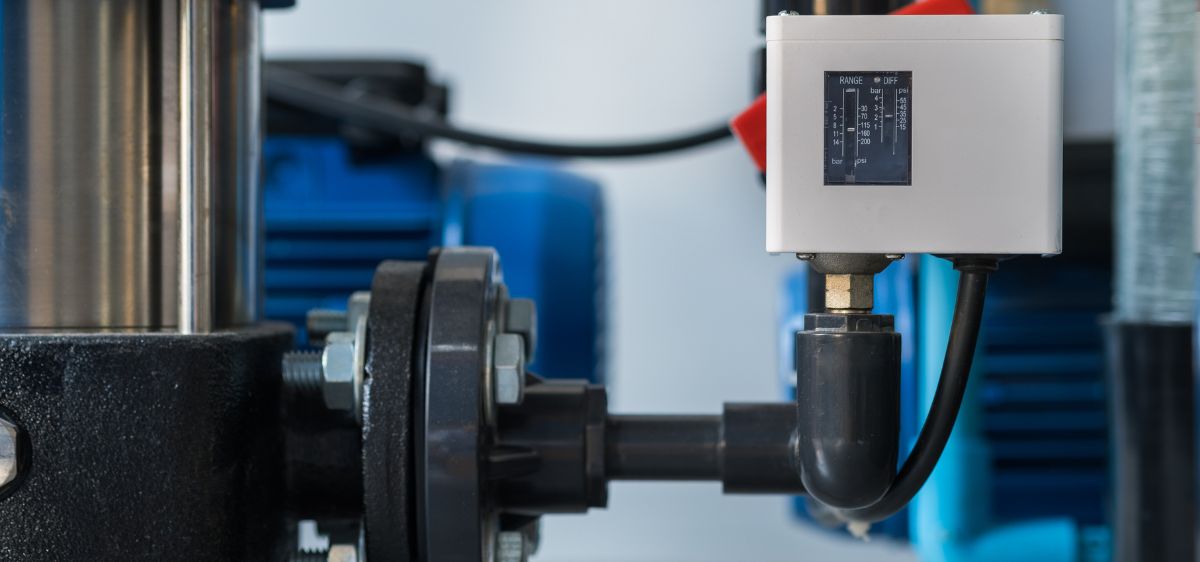

A common application for a high-pressure switch is in industrial hydraulic systems. These switches are crucial for monitoring and controlling pressure levels to ensure safe and efficient operation of hydraulic machinery.

What is a High Pressure Switch?

A high-pressure switch serves a crucial purpose in various industrial, manufacturing, and commercial settings. Think of it as a vigilant guardian that keeps watch over pressure levels, ensuring they don’t venture into unsafe territories. It’s like the safety valve on a hot water system that releases steam before the pressure gets too high. In many ways, this small but powerful control device plays a similar role.

Now imagine working with heavy machinery or large-scale HVAC systems – these are just some examples of where high-pressure switches come into play. Their job is to actuate when pressure reaches a specific threshold, thereby preventing dangerous situations that may lead to broken equipment or costly accidents.

The Functioning of a High Pressure Switch

The magic behind how high-pressure switches operate lies in the principle of pressure-induced mechanical deformation. When the pressure within a system hits a predefined level, it triggers a mechanical change in the high-pressure switch. This transformation then activates its electrical contacts, opening or closing them as required.

In simpler terms, it’s like a trigger that responds only when certain conditions are met—when the pressure hits a critical point.

Take an air compressor, for instance. When the pressure builds up and hits a predetermined limit, the high-pressure switch springs into action by turning off the compressor motor. As soon as the pressure falls back within safe levels, the switch reverts to its initial state, allowing the compressor to start again without any hiccups.

What makes these switches indispensable is their reliability and ability to ensure that pressure remains within specified limits at all times. This is especially vital in environments such as hydraulic systems where even tiny fluctuations can cause substantial damage and disrupt operations.

DID YOU KNOW? High-pressure switches are also designed to be extremely durable and resilient, capable of withstanding environments where pressures reach levels exceeding 1000 psi!

So there you have it—an overview of what high-pressure switches are and how they function in various industrial applications. These devices continually prove their worth by keeping systems running smoothly and most importantly, safely.

As we grasp the role and importance of high-pressure switches in maintaining safety and efficiency in various systems, we now turn our attention to delving into their specific functioning mechanisms.

Functioning of High Pressure Switches

Imagine a sophisticated watchdog that’s always on alert, ready to sound the alarm when things get too intense. High pressure switches perform a similar role in various pneumatic and hydraulic systems. They keep an eye on pressure levels, stepping in to take action when things reach critical points.

How They Work

These switches respond to changes in pressure within their operating range. When the pressure reaches a specific point, the switch takes action by either opening or closing an electrical circuit. This triggers specific actions within the system, such as activating a pump, shutting down a compressor, or triggering an alarm to alert of dangerously high pressure levels. The snap-action electrical device is activated by an elastomer diaphragm or piston, resulting in a decisive response to changes in pressure. This “no-creep” design ensures that the switches maintain their contacts either open or closed until a precise set point is reached. At that critical juncture, they snap over center to a new state and remain there until the pressure distinctly lowers, prompting the switches to snap back to their initial state.

To put it into perspective, think of a thermostat that senses when the temperature climbs too high and turns off the heater – high-pressure switches operate similarly but respond to pressure levels instead of temperature.

Ensuring Safety and Efficiency

By swiftly responding to variations in pressure, these switches play a crucial role in preventing damage or malfunctions due to excessive pressures. In applications such as industrial machinery or hydraulic systems, where high pressures are at play, these switches act as safeguards against catastrophic failures that could result in severe damage or even hazards for operators.

Consider them as guardians of operational safety and efficiency — stepping in when needed to maintain smooth operations and prevent potentially harmful conditions.

With an understanding of their functioning and purpose, it becomes clear why regular maintenance of high-pressure switches is paramount for ensuring their reliable operation within various industrial and mechanical systems. From hydraulic power units to pressure monitoring systems, the proper functioning of these switches directly impacts the safety and productivity of these critical systems.

By exploring their functioning and importance in maintaining operational safety, let’s now delve into the many control mechanisms and sensors associated with high pressure switches.

High Pressure Switch Control and Sensors

The efficiency and reliability of high-pressure switches heavily rely on their control mechanisms and sensors. The sensors used in these switches play a crucial role in detecting pressure changes, catering to various applications by adapting to different pressure ranges based on specific system requirements. For instance, sensors can be based on mechanisms like diaphragms, pistons, or bourdon tubes, each serving distinct purposes in handling varying pressure levels.

Let’s delve deeper into this. Diaphragm sensors, for example, are often used in applications where the pressure range is relatively low. They primarily function by using a flexible membrane to detect changes in pressure. On the other hand, piston-based sensors are employed where higher precision is required, leveraging a piston’s movement to gauge pressure fluctuations.

Additionally, bourdon tube sensors are ideal for applications with high pressures and are known for their robustness in withstanding such conditions. The choice of sensor mechanism is crucial as it directly impacts the accuracy and reliability of pressure detection within a system.

Moving on from the sensors, we must understand how these input signals are utilized by the control mechanism to regulate pressure within the system. The intricate dance between sensor input and electrical signal conversion is what enables these switches to effectively manage high pressures.

The control mechanisms translate the input from the sensor into electrical signals that ultimately dictate when the switch should activate or deactivate. This process governs the regulation of pressure within the system, ensuring it operates within the desired parameters.

In practical terms, let’s consider a high-pressure switch installed in an industrial hydraulic system. When there’s a surge in pressure beyond acceptable limits, the sensor detects this change and relays this information to the control mechanism. Based on this input, the control mechanism sets off a series of actions that could involve activating relief valves or shutting down certain components to bring the pressure back under control.

Effectively managing pressure through these robust control mechanisms and sensors ensures the smooth operation and longevity of machinery fundamental to industrial operations. It underscores the critical role these switches play in maintaining safety and efficiency in high-pressure systems.

Transitioning from the intricate workings of high-pressure switches, let’s now explore the crucial components and mechanisms that power these engineering marvels.

Components and Mechanisms

High-pressure switches are more than simple “on” and “off” devices. They’re intricate systems composed of various components that work together to ensure precise pressure regulation.

The Pressure Sensor

At the heart of a high-pressure switch is the pressure sensor, responsible for detecting pressure changes. This sensor acts as a watchful guardian, continually monitoring pressure levels and signaling the actuator when there’s a deviation from the set parameters. Modern pressure sensors offer enhanced accuracy and reliability, making them an indispensable part of the switch mechanism.

The Actuator

Upon receiving signals from the pressure sensor, the actuator swings into action. It acts as the executor of change, responding to the sensor’s input by adjusting the pressure settings to bring it back within the desired range. Whether it’s increasing or decreasing pressure, the actuator efficiently carries out its instructions to maintain precise control.

Electrical Contacts Management

Lastly, the electrical contacts play a crucial role in managing the flow of electricity based on the actuator’s response. These contacts are like traffic controllers, ensuring that power is directed appropriately based on the signals received from the actuator. By regulating electricity flow, they contribute to maintaining a stable and controlled environment, allowing for seamless operation of the high-pressure switch.

In unison, these components create a finely tuned orchestra of function, ensuring that high-pressure switches operate with precision and reliability. Working seamlessly together, they form an essential part of numerous industrial and commercial systems where precise pressure control is paramount.

Understanding how these components function together provides insight into how high-pressure switches effectively manage and regulate pressure in various applications.

Temperature and Level Management in High Pressure

High-pressure switches do more than just manage pressure; they also handle temperature and liquid levels. In certain industrial and commercial settings, it’s crucial to monitor not only the pressure but also the temperature and liquid levels in various systems. These switches come with advanced features that enable them to oversee and regulate multiple parameters at once, making them incredibly versatile and adaptable across a wide range of applications.

Let’s take a closer look at why integrating temperature and level management is important. In many industrial processes, maintaining a specific temperature is critical for ensuring operational efficiency and safety. For example, in an HVAC system, high-pressure switches with integrated temperature management can help regulate the refrigerant’s temperature to ensure optimal performance while preventing potential damage due to overheating or freezing.

Similarly, in applications involving liquid levels, such as water tanks or chemical processing units, high-pressure switches equipped with level management functions play a critical role in preventing overflows or shortages that could disrupt operations or lead to safety hazards. The ability to monitor multiple parameters gives these switches a significant advantage in ensuring smooth and error-free performance across diverse industries.

Multi-Sensing Capabilities

The integration of multi-sensing capabilities in high-pressure switches allows them to gather data from various sources simultaneously. This feature enables them to detect potential issues or anomalies in real-time and trigger appropriate responses to maintain optimal operating conditions without the need for human intervention.

For instance, in an industrial boiler system, a high-pressure switch with multi-sensing capabilities can monitor not only the pressure within the boiler but also the water temperature and level to prevent dangerous situations such as overheating or low water levels that could lead to equipment damage or accidents.

The versatility offered by multi-sensing capabilities makes high-pressure switches invaluable assets in complex industrial setups where precise monitoring and control of multiple variables are essential for operational safety, efficiency, and regulatory compliance.

By understanding how high-pressure switches integrate temperature and level management functions, we gain insight into their adaptability and utility across a broad spectrum of industrial and commercial environments. The next step is to explore comparative data on their performance under varying temperatures for a more comprehensive understanding of their capabilities.

Practical Applications of High Pressure Switches

High-pressure switches are critical devices used in a wide range of industrial applications. They provide essential control and safety features across several industries, making them indispensable for maintaining optimal operating conditions and preventing potential hazards.

Hydraulic Systems in Heavy Machinery

In heavy machinery, such as bulldozers and excavators, hydraulic systems rely on high-pressure switches to monitor pressure levels. These switches play a critical role in ensuring the safe and efficient operation of heavy equipment by providing real-time feedback on hydraulic fluid pressure. This allows for immediate adjustments to maintain the desired pressure levels, enhancing the performance and safety of these powerful machines.

Pneumatic Systems in Manufacturing

In manufacturing facilities, pneumatic systems depend on high-pressure switches to regulate air pressure within production lines. These switches enable precise control over air compressors and actuators, ensuring smooth and accurate operation of pneumatic machinery. By monitoring and maintaining optimal pressure levels, high-pressure switches contribute to the reliability and efficiency of manufacturing processes.

Pressure Monitoring in Chemical Processing Plants

Chemical processing plants utilize high-pressure switches to monitor and manage pressure within various stages of production. The switches play a vital role in ensuring the safety and integrity of processes involving volatile substances by providing precise pressure control. This helps prevent over-pressurization and ensures that critical chemical reactions occur under controlled conditions, safeguarding both personnel and equipment.

Pressure Control in Industrial Refrigeration and Cooling Systems

In industrial refrigeration and cooling systems, high-pressure switches are essential for maintaining optimal pressure levels within refrigerant circuits. These switches facilitate the regulation of high-pressure conditions, preventing potential damage to the system while enabling efficient cooling operations. By monitoring and controlling pressure fluctuations, these switches support the reliable performance of industrial cooling processes.

Safety Control in High-Pressure Air Compressors

High-pressure air compressors rely on dedicated switches to ensure safe operating conditions by monitoring pressure levels within the compressor systems. These switches serve as critical safety components, preventing over-pressurization and safeguarding against potential mechanical failures or hazards. By promptly signaling deviations from safe pressure ranges, these switches help maintain operational integrity and protect against dangerous malfunctions.

The diverse applications of high-pressure switches underscore their instrumental role in maintaining operational safety, optimizing performance, and preserving equipment integrity across various industrial sectors.

As we’ve seen how high-pressure switches are vital across different industries, it’s crucial to consider the implications associated with attempting DIY repairs and legal compliance. This brings us to an important discussion on “Maintenance and Legal Concerns in DIY Repair Attempts.

Maintenance and Legal Concerns in DIY Repair Attempts

When it comes to the maintenance and repair of high-pressure switches, it’s crucial to recognize that these devices are critical components in various systems. While some basic maintenance can be carried out by end users or maintenance personnel, more intricate repair work and calibration should only be executed by qualified technicians with the necessary training, skills, and tools to handle these complex procedures safely and effectively.

It’s understandable that many individuals may feel inclined to try DIY repairs on their equipment to save costs or time. However, when dealing with high-pressure switches, such attempts can pose significant safety hazards if not properly executed. A simple mistake can lead to a malfunctioning switch, potentially compromising system operations and endangering personnel safety.

Moreover, engaging in DIY repairs without the required proficiency can result in non-compliance with industry regulations and standards. These regulations are put in place to ensure the safe operation of high-pressure systems and to prevent accidents that could result from faulty equipment. By attempting repairs without the appropriate knowledge and training, individuals risk violating those standards, which could lead to significant legal consequences.

For instance, improperly calibrated high-pressure switches in critical industrial processes could lead to catastrophic failures, jeopardizing not only the efficiency of operations but also the safety of the workforce. This underscores the importance of adhering to legal requirements and industry standards when dealing with maintenance and repair activities for high-pressure switches.

Consider that just as one would rely on a licensed electrician for complex electrical work in their home to ensure compliance with safety codes, proper functioning, and legal requirements, the same principles apply to maintaining high-pressure switch systems within industrial settings.

In light of these considerations, it becomes clear that seeking professional assistance for high-pressure switch maintenance and repair is not just about expertise but also about adhering to legal regulations and ensuring the safety and functionality of critical systems. If you’re looking for reliable high-pressure switches that meet stringent performance standards, ITT Neo Dyn products available at Southgate Process Equipment are a trusted option for quality and performance.

When dealing with the intricacies of high-pressure switch maintenance and repair, prioritizing safety, compliance with regulations, and functionality is paramount. Seek professional assistance when needed to ensure the reliability of your critical systems.